Modular Biomanufacturing Built for Real-World Production

Dapibuset’s modular biomanufacturing system enables producers to upgrade underused side streams directly at the source. |

Inoculate

Transform

Harvest

Dapibuset’s modular system is designed to operate where side streams are generated and where value can be created most efficiently.

The same technology platform supports different deployment models, from early collaboration to full on-site production

On-Site Deployment

Installed directly at farms or production facilities, where side streams are generated.

Processing on-site allows transformation at the optimal moment, before quality and functionality begin to decline.

This enables producers to integrate ingredient creation directly into existing operations.

Cluster Deployment

A shared bio-manufacturing platform serving multiple producers within a region.

In this model, several Dapibuset units are co-located in a shared facility, allowing multiple producers to access biomanufacturing capacity without deploying individual systems at each site. Side streams are sourced locall

Pilot and co-development setup

Pilot and co-development setup

A compact system for ingredient validation and collaboration using real side streams.

This setup supports testing, optimization, and application development while remaining fully aligned with the commercial platform.

DESIGNED FOR EFFICIENCY AT EVERY STEP

Performance values are indicative and based on internal testing and pilot deployments, benchmarked against conventional centralized processing methods.

Modular on-site biomanufacturing system

Up to 80% lower water use

Up to 10× lower energy demand

Delivers up to 50% lower operating costs

Designed to deliver consistent ingredients for food, feed and pet food

Dapibuset’s biomanufacturing system transforms underused side streams into stable, nutrient rich ingredients under controlled conditions.

By integrating process control, hygiene design and traceability from the start, the system delivers consistent ingredient quality suitable for food, feed and pet food applications. What begins as a local side stream becomes a reliable input that can be used, scaled and integrated with confidence.

Frequently asked questions

What types of side streams can be used?

Side streams originating from food and beverage factories and from agricultural production.

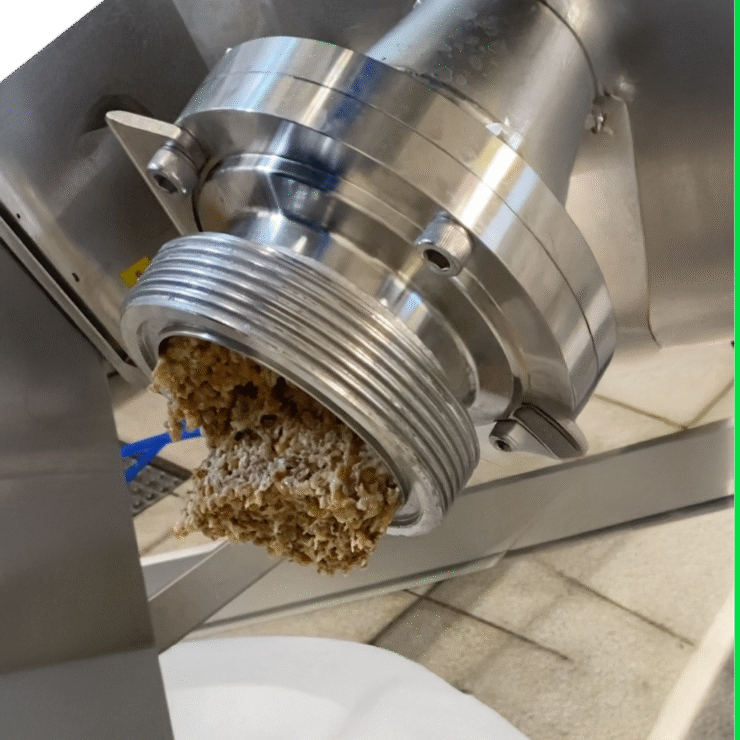

What ingredient formats are possible?

The process delivers stable ingredient outputs that can be further processed into dry powders, meals, or blended formats depending on the application and downstream use.

Is the system suitable for food, feed, and pet food applications?

Yes. The system is designed to meet food and feed hygiene requirements and supports use across food, feed, and pet food markets when operated within the relevant regulatory framework

Does the unit require specialized staff?

No. The system is designed for straightforward operation and can be run by existing production staff following standard training and operating procedures.

How is the process monitored and controlled?

The process is monitored through an integrated control system that tracks key parameters and supports consistent operation. This allows operators to maintain stable conditions and repeatable outcomes.

How long is a processing cycle?

A typical cycle runs over several days, depending on the side stream and the targeted ingredient characteristics.

Where can the system be installed?

The system is designed for installation at farms, production facilities, or shared processing sites where side streams are generated and handled.

Can the system scale?

Yes. Capacity can be increased by adding additional units or by clustering systems to match volume requirements.

How does the system handle variability in side streams?

The process is designed to work with natural variation in side streams. Operating parameters can be adjusted to maintain consistent transformation and ingredient quality.

What happens after the ingredient is produced?

It could be directly used or it can be handled using standard processing steps such as drying, milling, or blending, depending on the final application and market requirements.